Stahl Liebherr 922

-

-

Anyody?

-

Hi Calum,

Changing the oil won't improve the performance of your excavator. I would suggest installing a brushless pump, although I am not familiar with the LIebherr 922. You might get a higher speed and more power with it. But maybe someone in this forum who owns a Liebherr 922 could better support you?

Good luck.

Kind regards

Bjoern -

Hi Calum

I believe its a used machine as the producer for the chassis doesn`t exist anymore.

You never know what the preowner has experimented with the machine.

But the producer for the hydraulic system is still existing.

In the normal configuration the hydraulic system is sufficent.

Check:

- Is the oil clean?

- Is the filter clean?

- Do the valves open correctly to the full extend?

- Does the pump produce enough pressure?

Hope I could help a bit.

greetz chris

-

I meant to say it was 'new' to me..

I changed the oil in the digger and the only way to make the movements quicker is to adjust the pressure screw. It works well and is able to dig outside

Would there be a motor better suited to the Leimbach pump?Calum

-

Hi Calum

Again the question: Do the valves open to the full extend?

As i said, in the normal configuration the speed of the system is sufficent.

There is a set of a brushless-motor for the pump available that increases the pumps rpm.

But it increases tear and wear of the pump.

And increasing only the pressure easily blows your hoses.

Up to 12 bar should be enough.

greetz chris

-

Hi Calum

I found 2 videos.

The 1st one seems to be the original speed and the 2nd one is running with 16bar, which is a little bit too fast for my opinion.

I own a 944 with original 17bar.

I normally run with only 75% of the pumps power.

I don`t like "race-digging".

https://www.youtube.com/watch?v=3TS6Ziv3TAw

https://www.youtube.com/watch?v=jUTYXN7aeRA

and the link to the Leimbach brushless-motor:

http://www.leimbach-modellbau.de/

greetz chris

-

Hello Chris, thank you for the reply

Can you tell me the best way to check the valves are open completely? I use a Robbe f16 the end points on the servo's are all set at 100% but for the main boom I have to manually set the servo or the valve will stay open causing the boom to lift.

This could be my problem, is there a way I can set the servo's?Greeting's Calum

-

Hi Calum

With an F16 it is a little bit complicated.

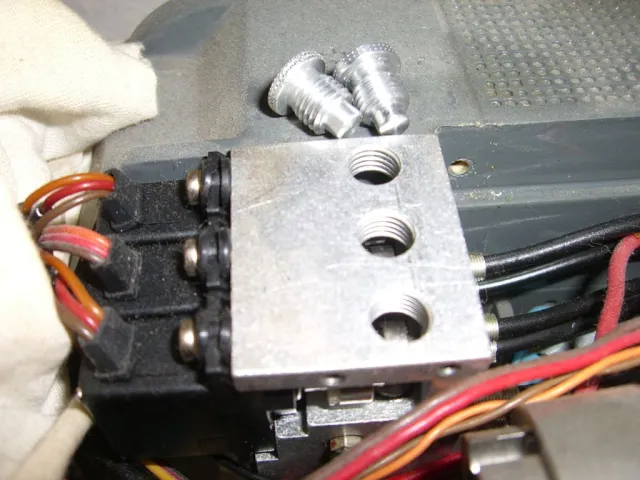

The valves come with relatively big screws separatly.

Now the method to adjust:

- take off the servo from the valve and and set it with the F16 to the neutral-point.....trimming should be zero.

- then take one of the big screws and figure out the close-point (neutral-point) of the valve by screwing it by hand.

- of course the oilpump should run during that process.

- then fasten the servo again with the valve.

According to my experience this is the best method to adjust the valves without a computerized RC.

May be the pic helps what i mean.......

greetz chris

-